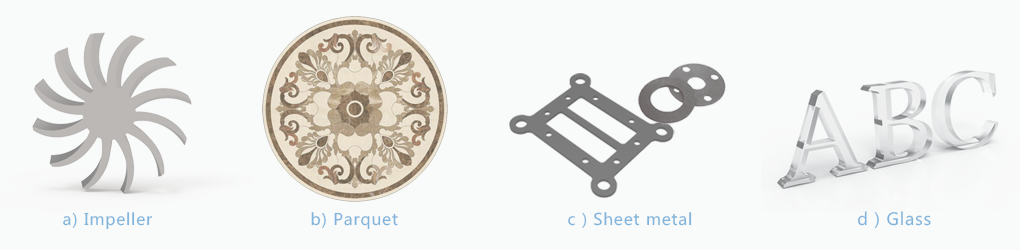

Weihong waterjet cutting control system covers two-to-five axis motion control, among which five-axis waterjet cutting CNC system, is the earliest and most mature system in domestic market. It can achieve dynamic five-axis cutting and solve the tapper and trailing problems of high-pressure waterjet technology. It has been widely applied in cutting of metal, stone, glass and ceramic, etc.

Weihong glass cutting control system boasts industry-leading functions such as following normal line of the rotary-axis, eccentricity compensation, precise cutting pressure control by analog variable, and it has been widely applied in machining of glass of different uses.

Applied in manufacturing of stone parquet and ceramic parquet

The system features excellent hardware performance, integrating dual-core CPU with 2.17GHz main frequency, 60G SSD, 2G RAM...... control card unit, and NcStudio motion control software.

Learn More

The system features good real-time performance, with“Communication card + Lambda controller“ combination, RS485 interface, serial communication technology and 10Mbps baudrate.

Learn More

Applied in 3D cutting with large angle

For two-dimensional figures with chamfer, it can realize higher cutting efficiency and better cutting result. It supports angle cutting as large as 45 degrees, high-precision three- dimensional cutting, and importation of 2D figures.

Learn More

The system features good real-time performance, with“Communication card + Lambda controller” combination, RS485 interface, serial communication technology and 10Mbps baudrate.

Learn More

The system features excellent hardware performance, integrating dual-core CPU with 2.17GHz main frequency, 60G SSD, 2G RAM...... control card unit, and NcStudio motion control software.

Learn More

Applied in irregualr-shaped glass cutting and glass splicing

The system features excellent hardware performance, integrating dual-core CPU with 2.17GHz main frequency, 60G SSD, 2G RAM...... control card unit, and NcStudio motion control software.

Learn More

The system features good real-time performance, with“Communication card + Lambda controller“ combination, RS485 interface, serial communication technology and 10Mbps baudrate.

Learn MoreIt can realize 3D cutting with adoption of AC five-axis high- precision cutting head, and can realize chamfer cutting together with four/five-axis control system, which has been widely applied in industry of stone splicing and ceramic splicing, metal sheet manufacturing, irregular- shaped glass cutting, etc.

It has been widely applied in rapid cutting of regular-shaped glass, manufacturing of complex figures with following normal function, irregualr -shaped glass cutting as well as glass splicing for home decoration.