To meet requirement of machining efficiency, precision and flexibility in high-end motion control, Weihong Company launches innovative HST algorithm after years of endeavor, which can greatly optimize machining performance of engraving and milling machines, CNC tapping machine etc.

Taking high-speed trapezoid (HST) interpolation algorithm as the core, the new generation HST algorithm tries to make the best of the following: G00 movement, toolpath pre-processing and self-adaptive smoothing of small lines.

High Speed

Inmetal working industry, there is a common challenge for NC system because of complex toolpath and processing of small lines. HST algorithm improves processing of small lines by at least 100%, and has been proven to be a good solution to high speed machining of complex toolpath.

Optimizing machining efficiency of curves and short lines

Comparing with general algorithm, Weihong HST algorithm excels in both flexibility and ability to accelerate and decelerate in short time. In case of manufacturing of human mask mold, it increases the machining efficiency by 9%~20%.

Performance comparison of general algorithm and Weihong HST algorithm:

Acceleration

(mm/s^2) |

Jerk

(mm/s^3) |

General Algorithm

(second) |

HST Algorithm

(second) |

Efficiency Increased

(%) |

|

800 |

150000 |

1378 |

1244 |

9.72 |

|

80000 |

1527 |

1254 |

17.88 |

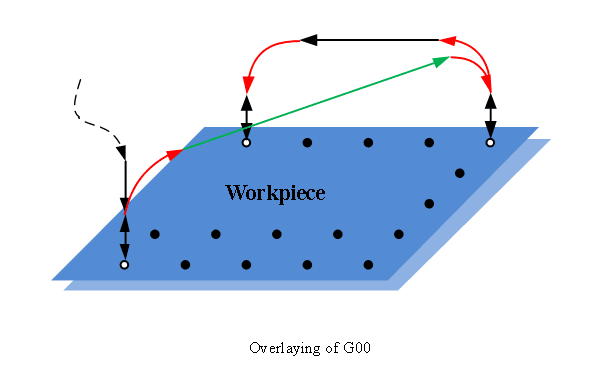

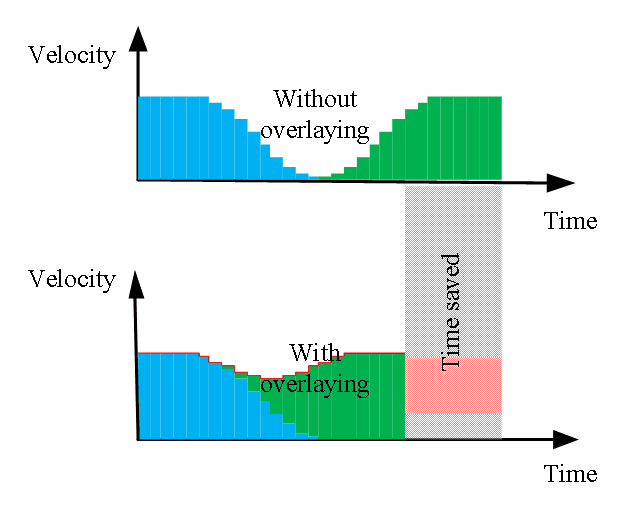

Optimizing connections of rapids

With Weihong HST algorithm, Weihong NC system can automatically recognize the processing of tool engagement in CAM, and improves the following:

1. Increasing efficiency with full consideration of safety

2. Optimizing acceleration and deceleration at high speed by fully taking advantage of mechanisms and kinematics

3. Using overlaying of fast positioning to decrease rapids motion time to the largest degree

High Quality

With the innovative pre-processing of toolpath and self-adaptive smoothing of small lines, Weihong HST algorithm greatly contributes to the surface finish quality.

Pre-processing of toolpath

Weihong HST algorithm enhances continuous and overall processing of the toolpath. Smoothness of toolpath can be improved, so as to velocity changes, which both contributes to the machining effect in the end.

For some CAM toolpath that is relatively poor in smoothness, there may be some unsatisfactory burs and chatters on the surface. HST algorithm can improve the toolpath smoothness, and ultimately improve the finish quality of the surface.

Self-adaptive smoothing of small lines

Velocity changes because of small lines may cause poor performance on some curved surfaces on the one hand; on the other hand, changes of certain frequency may cause resonance of mechanisms as well. Besides,frequent velocity changesmay cause damage to cutting tools.

Self-adaptive smoothing of small lines can effectively solve the problem of highly frequent fluctuation under high speed conditions, unstability of mechanical motion speed, and cutting tool wear.

A powerful and intelligent algorithm lays a solid foundation for CNCsystem. Weihong HST algorithm will be a good choice for you, for highly efficient and intelligent motion control.